Machinery

Fault Signature simulator

Bring Industry Faults to life right before your eyes!

Experience | Train | Innovate

30+

Machinery Fault

Simulator

Experience the distinction between machine fault and healthy signatures at a glance with our advanced simulation technology.

TMFSS

Compatible with most faults encountered in the industry, our Addon Kit empowers you to simulate a wide range of faults, enhancing your diagnostic capabilities.

30 +

Fault Simulator

Simulate over 30 faults effortlessly with a single device.

Expert

Assistance

Expert assistance and ongoing updates for our products and software solutions.

Safe and

Effective

Your safety is our top priority.

Reliable &

Affordable

Our products offer both reliability and affordability

Training

Kits

We cover every detail in our comprehensive training kits

Handy &

Easy Switcher

Easy to handle and adaptable for quick setup changes across different experiments.

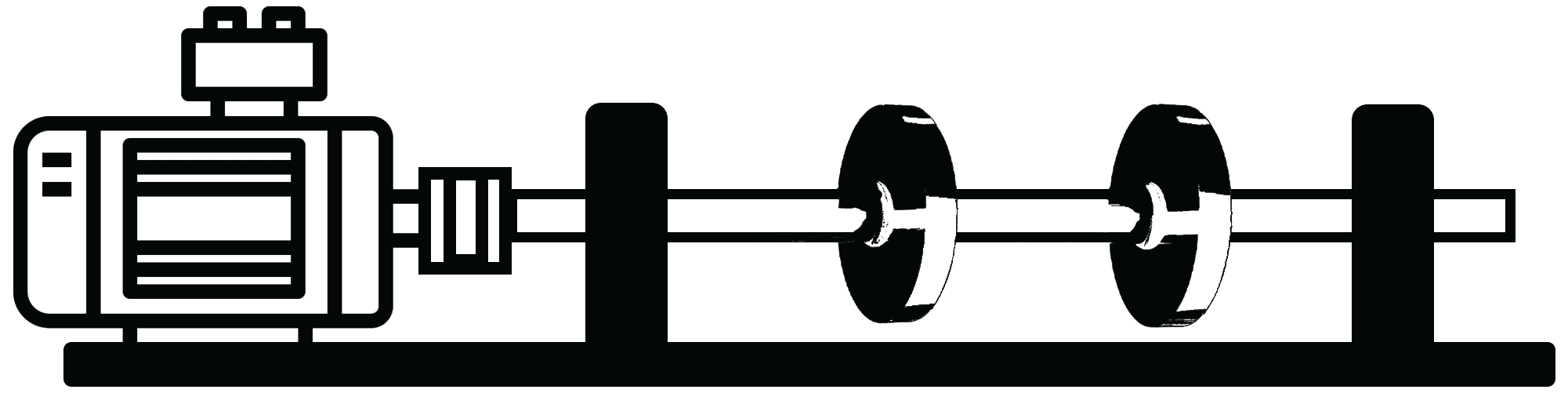

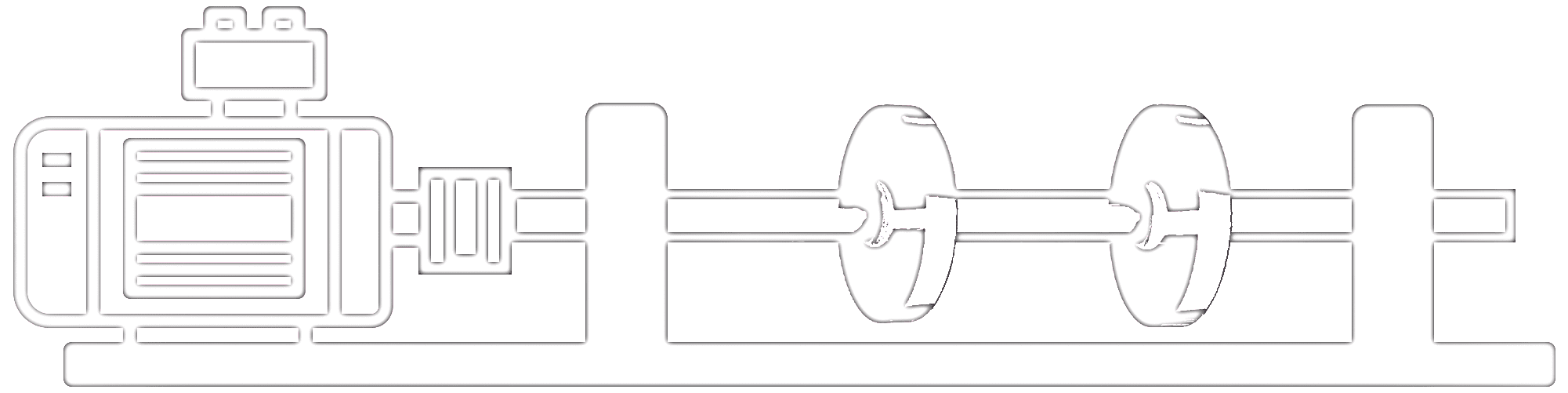

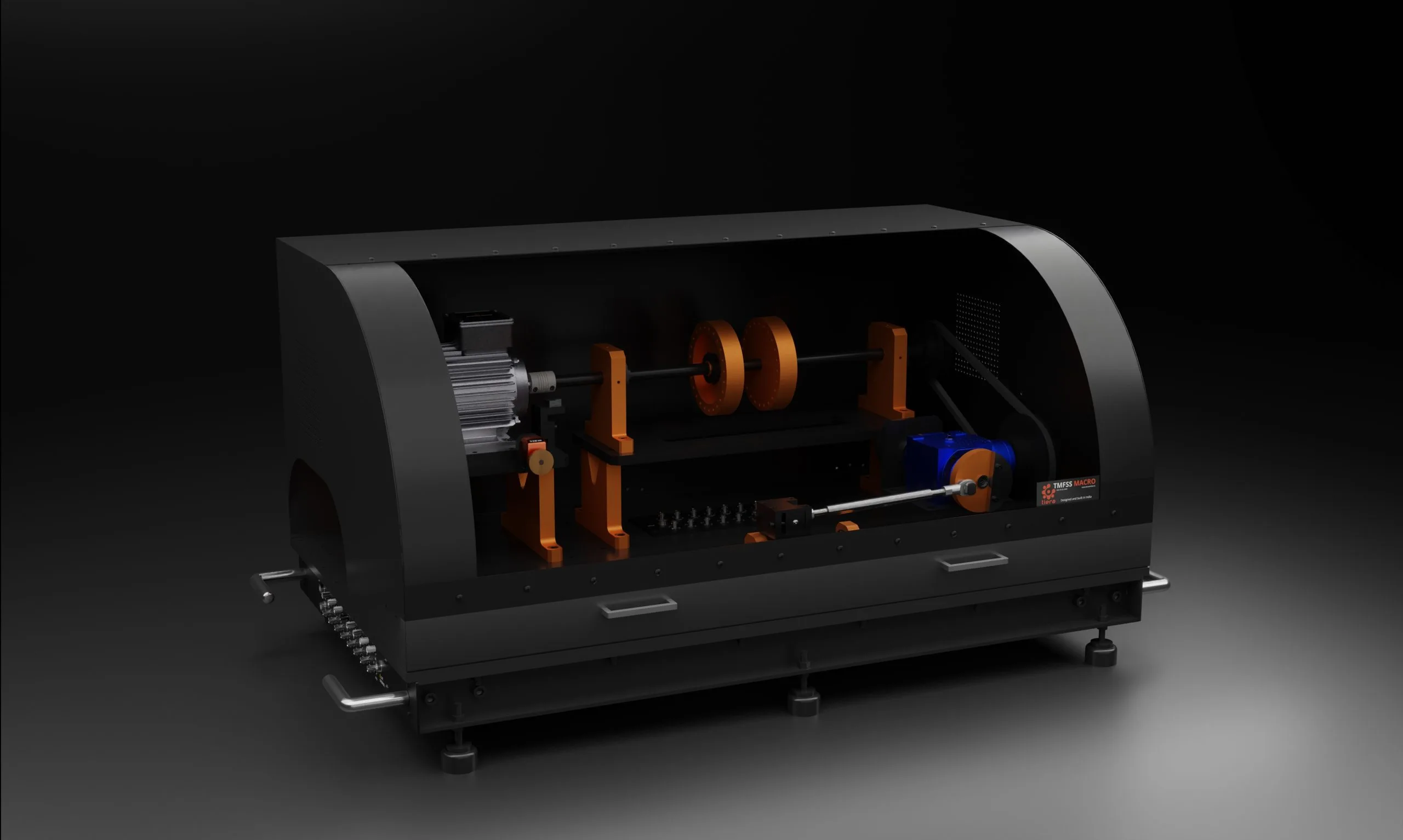

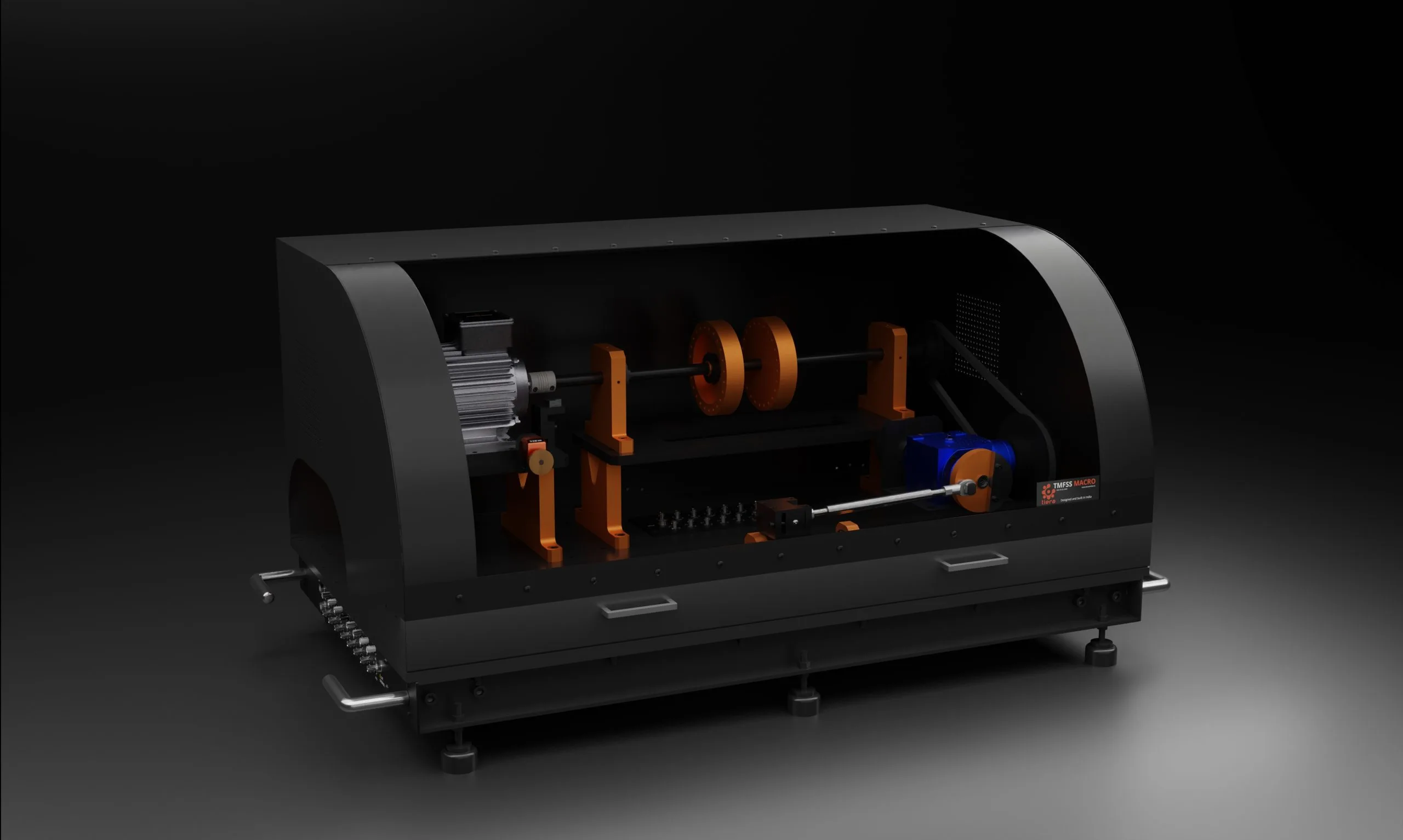

MACHINERY FAULT

SIMULATOR

Fault Simulator offers realistic simulation of various machinery faults, enabling in-depth understanding and training in vibration analysis and diagnostics.

TMFSS Macro can simulate over 30+ real-world faults commonly present in the industry.

Faults that we can simulate

- Basic Misalignment Simulation

- Unbalance simulation

- Bearing Fault Simulation (excl. Cocked Bearing)

- Foundation Looseness

- Resonance Simulation KIt

- Coupling Studies (COS)

- Mechanical Rub

- Cocked Bearing

- Bent Shaft

- Finned Rotor

- Eccentric & Cocked Rotor Simulation

- Belt Drive Fault

- Cracked Shaft

- Reciprocating Mechanism

- Damping

- Sleeve Bearing

- Gear Box Fault

- Electrical Motor Fault

- Pump cavitation

- Accelerated Bearing Wear

- Lockable Bearing Kit

- Included In basic Kit

- Addon Kits

TMFSS Macro can simulate over 30+ real-world faults commonly present in the industry. Read More

Faults that we can simulate

- Included In basic Kit

- Addon Kits

TMFSS MACRO

- Add-On Kit for More Industry Faults

- Versatile Testing

- Wide Range of Fault Simulations

- Advanced Analysis Capabilities

- Educational & Research Focus

- Simulate 30+ Industry Faults

TMFSS MINI

- Limited Add-on Kits

- Simulates 7+ machinery faults

- Educational Focus

Tiera's Product

Series.

Tiera’s Product Series for both Sound & Vibration.

Simulation Software

for

Sound & Vibration

Best Simulation software which help to simulate all real cases in simple cases

Contact

Our Team.

We’re a dynamic team of vibration specialists, dedicated to providing top-tier testing services and equipment. Our expertise lies in helping industries ensure product reliability and safety through advanced vibration analysis and testing.

FAQ

What is the Machine Fault Signature Simulator, or TMFSS?

The TIERA Machinery Fault Signature Simulator (TMFSS) is a portable and versatile machine designed to mimic various typical machinery problems and faults encountered in industrial settings. This is a Make-in-India product that is designed and manufactured in India. These faults include resonance, shaft misalignment, rolling element bearing defects, rotor unbalance, bent shaft, rubbing, and more. Additionally, the simulator can be equipped with specialized kits to simulate specific issues such as pulley-belt vibrations, gearing defects, centrifugal pump wear, accelerated bearing life tests, and more.

The primary purpose of TMFSS is to provide a controlled test environment where users can replicate rotating machinery faults. This allows for hands-on learning, sensor prototype testing, and qualification of equipment. Moreover, the simulator serves as a valuable tool for developing algorithms related to predictive or preventive maintenance and conducting research on signature feature extraction and signal processing techniques.

In summary, the TMFSS offers a practical platform for industrial professionals, researchers, and engineers to experiment with various machinery fault scenarios, facilitating skill development, innovation, and optimization of maintenance strategies.

Who should buy TMFSS?

Motor and Bearing Manufacturers: They can assess the performance and durability of new motors and bearings at different RPM and loads, and also create specific loading conditions and faults based on test standards.

Maintenance and Reliability Engineers: They can utilize the simulator to learn and train the workforce in order enhance machinery reliability and reduce downtime by early detection of faults.

Defence and Aerospace Industry: They can study high and low-speed rotor dynamics to develop effective turbines, pumps, and other devices, as well as train new recruits in condition monitoring.

Data Scientists: They can use the simulator to develop and test machine learning/AI algorithms for fault detection and diagnosis using simulated vibration signals.

Researchers and Students: They can leverage the simulator for academic research on machinery faults, signal processing techniques, and condition monitoring solutions. The calibrated faults also enable the analysis of system degradation trends.

Product Development Teams: They can use the simulator to develop products like vibration monitoring devices/sensors and test their performance and features in the laboratory before field tests, saving development time.

Do I get all the sensors, DAQ and software with TMFSS starter kit/advanced kits?

No. The TMFSS starter/advanced kit contains an inbuilt tachometer with analog output and includes software for motor control via WiFi (Except micro). The TMFSS Macro and advanced kit of the Mini version provide a VFD programming cable and software. However, accelerometers, portable tachometers, proximity probes, DAQ systems, and analysis software are not part of the bundle.

For meaningful data acquisition and analysis, essential accessories like accelerometers, proximity probes, current clamps, power supplies, mounting devices, cabling, DAQ systems, analysis software, strobe, tachometer, and trigger pulse generator are necessary. If users wish to explore more advanced features, specialized software like balancing tools, advanced TVIB modules such as order tracking, orbit module, and modal analysis programs can be beneficial.

What are the benefits of TMFSS over imported brands?

-

-

Comprehensive Solution

The TMFSS offers an all-in-one solution, bundled with TIERA’s budget-friendly PhonoVibe series DAQ and versatile TVIB software. The package includes cost-effective accelerometers, mounts, and accessories, making it a unique and adaptable offering in the market.Cutting-edge TOLEARNVIBE Software

Subscribers gain access to TIERA’s TOLEARNVIBE vibration training software, which provides hands-on experience through practical learning opportunities. This software, available with all subscription variants, emulates a real-world vibration analyzer front end, enhancing practical skills.ISO CAT I or II Online Courses

Buyers can subscribe to our affordable ISO CAT I or II online courses at https://learn.tieraonline.in/. These courses offer valuable insights into theory and practical signal processing, complemented by practical use of the TMFSS simulator. We also provide courses in Experimental Modal Analysis, Finite Element Methods, and more for a comprehensive learning experience.Affordable Spare Parts

TMFSS offers cost-effective, make-in-India spare parts, ensuring hassle-free maintenance and long-term usability.Customizability

TMFSS can be customized to meet individual user requirements, offering a personalized experience for diverse needs.Comprehensive Training

The TMFSS kit includes video tutorials and hardcopy manuals, providing thorough guidance on operations and functionalities.

-

Can TMFSS be used for ODS and Modal analysis while teaching real-life applications?

Certainly! The TMFSS offers an extensive range of attachments that can simulate various vibration signatures, making it an excellent platform for conducting operating deflection shape (ODS) training. ODS is a technique used to visualize and understand the dynamic behavior of machinery by studying its deformations during operation.

To do ODS and EMA, users will require the appropriate hardware and software. This includes specialized sensors and data acquisition tools to capture the structural responses of the machine during operation. The acquired data can then be analyzed using relevant software to generate ODS animations and insights into the machine’s behavior. TIERA offers a cost-effective MODALVIEW software that can do ODS and EMA using the data acquired from PhonoVibe DAQ.

How does it simulate real world machinery and how do I scale the data?

The TMFSS (Machinery Fault Simulator System) is a scaled down model that replicates real-world machinery conditions. It achieves this by using full-sized commercial components and critical design techniques. It is assembled on a solid and rigid foundation to minimize undesired factors ensuring repeatability. To assure the reliability of the simulator’s results compared to actual machines, the TMFSS generates motion that closely resembles larger or smaller machines.

However, quantitatively scaling the data during modeling presents unique and complex challenges. Predicting specific cases without prior testing is difficult. Therefore, TIERA emphasizes experimental validation to validate the simulator’s accuracy against real-world machinery. Fine-tuning the simulator’s parameters, such as mass, stiffness, and damping, based on actual measurements helps achieve better alignment with real vibration responses.

Careful consideration of limitations and assumptions in the simulation model, including material properties and boundary conditions, is crucial. Through meticulous validation against real-world data, analysts can confidently rely on the Fault Simulator’s outcomes to gain meaningful insights into real machinery behavior.

Why do I need to buy different accessory kits for TMFSS?

The fundamental Machine Fault Signature Simulator serves as a “variable speed rotor kit” that allows controlled investigations into misalignment and balance issues. It offers flexibility in studying specific problems by enabling the attachment of various “kits” to the machine, which vividly demonstrate the desired phenomena. These kits are designed to showcase specific faults and include resonance, rub, gearbox, belt drive, centrifugal pump, reciprocating mechanism, motor misalignment, among others.

In essence, the Machine Fault Signature Simulator provides a versatile platform for researchers and analysts to explore different fault scenarios and understand their effects on machinery. By utilizing the appropriate kit for a particular fault, users can gain valuable insights into the behavior and vibration signatures associated with common faults found in real-world machines. This allows them to study and analyze various fault conditions in a controlled and repeatable manner, contributing to a deeper understanding of condition monitoring and vibration analysis techniques. Additionally, the simulator’s ability to vary rotor speed enables the examination of faults under different operating conditions, making it a valuable tool in diagnosing and mitigating issues in industrial machinery.

What experiments can I run with each accessory kit?

TIERA offers a comprehensive manual that provides in-depth guidance for conducting laboratory exercises. The manual covers a wide range of experiments, including detailed instructions on topics like shaft alignment, sheave/sprocket alignment, resonance, eccentric rotor, unbalance, defective bearings, phase relationship, reciprocating motion, gearing issues, belt drives, foundation stiffness, centrifugal pumps, motors, and more. Users are encouraged to seek assistance from TIERA engineers for specific applications and further support.

Explore Our

Insights and Innovations,

Unlock Expert Knowledge and Latest Updates, Read More

Leave your message here

Our team will get back to you soon